Introduction

Every beautifully printed book starts long before the first page is produced. Inside a professional book printing factory, creativity meets precision — blending art, technology, and quality control at every stage.

From your initial design to the moment you hold your finished copy, the book printing process is a coordinated journey. Let’s walk through each stage to see how printing suppliers bring your ideas to life.

1. Design and File Preparation

Everything begins with your digital design. The printing team checks layout files for resolution, fonts, and color settings.

A prepress technician ensures each file is print-ready, converting artwork to CMYK mode and adjusting margins and bleeds.

Factories often send a digital or physical proof for client approval before printing starts — ensuring accuracy in color and layout.

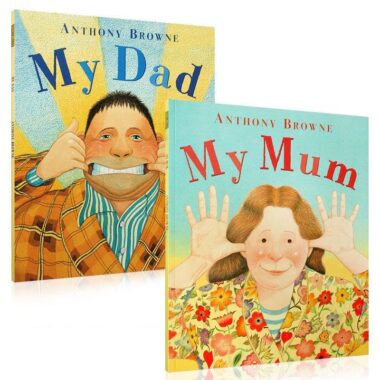

2. Paper and Material Selection

Next comes material choice. The factory helps you select the right paper weight, coating, and texture to match your book type.

Glossy paper works best for catalogs and magazines, while matte or uncoated paper gives novels and educational books a natural look.

This decision directly affects the feel, readability, and perceived quality of your publication.

3. Printing and Color Control

Once materials are ready, high-speed offset or digital printers begin production. Every color is calibrated precisely according to the proof sample.

Modern book printing suppliers use automated systems to maintain consistent ink levels across thousands of sheets.

Technicians regularly inspect each batch to guarantee uniform tones and sharp images.

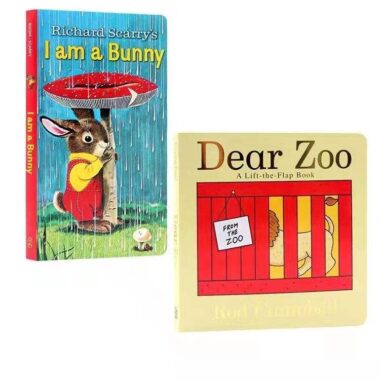

4. Binding and Finishing

After printing, pages are folded, gathered, and bound. The binding type depends on your project:

Perfect Binding for softcovers

Sewn Binding for premium hardcovers

Saddle Stitching for booklets or magazines

Finishing touches like lamination, foil stamping, or embossing add texture and professionalism to your final product.

5. Quality Inspection and Packaging

Before delivery, every book passes through a strict quality check. The factory’s QC team verifies trimming, binding strength, and color consistency.

Books are then shrink-wrapped or packed in export-ready cartons with protective padding.

This ensures each shipment arrives in perfect condition — ready for sale or distribution.

6. Global Delivery and Support

Once production is complete, your books are carefully shipped worldwide by air or sea.

A trusted book printing factory provides end-to-end support — from customs paperwork to post-delivery tracking — ensuring a smooth experience for international clients.

Conclusion

Behind every printed book is a team of designers, technicians, and quality experts working in harmony.

From the first design file to the final shipment, a professional book printing supplier ensures your project receives care, precision, and creativity at every stage.

Choosing the right factory means more than just getting books printed — it means turning your vision into a tangible story worth sharing.