📘 Introduction

When planning a custom book printing project, one of the first questions buyers ask is: “How much will it cost?” The answer depends on a combination of design choices, production methods, and material selection.

Professional book printing factories use a cost structure based on quantity, materials, and finishing. Understanding these factors will help you plan smarter and make cost-effective decisions without compromising quality.

📏 1. Book Size and Page Count

Larger books require more paper, ink, and printing time. Similarly, books with higher page counts cost more to produce.

For example, a 100-page softcover novel will cost less than a 300-page photo book with full-color illustrations. Discussing the intended size early helps your supplier choose the most efficient layout for printing.

📄 2. Paper Type and Quality

Paper is often the most significant cost factor in book printing.

Standard paper: Affordable, suitable for novels and text-heavy publications.

Coated paper: Used for catalogs or magazines with images.

Specialty paper: Textured, recycled, or FSC-certified options increase cost but enhance brand image.

Your book printing supplier can recommend paper that balances quality and budget.

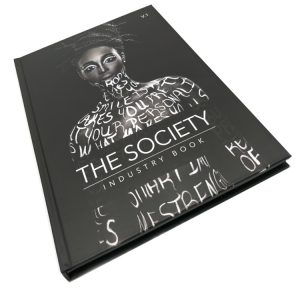

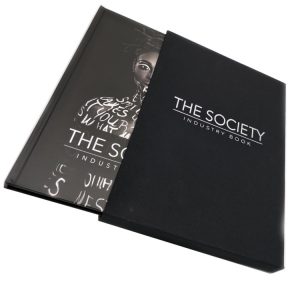

🔗 3. Binding and Cover Options

Binding choice has a major impact on cost and durability:

Saddle stitch: Cheapest, ideal for thin booklets.

Perfect binding: Clean and affordable for softcovers.

Hardcover / case binding: Premium option with higher labor cost.

Additional cover enhancements like foil stamping or embossing will also add to total expenses.

🎨 4. Printing Method: Offset vs. Digital

Offset printing is cost-efficient for large quantities and provides superior color consistency.

Digital printing suits smaller runs, allowing flexibility and quick turnaround.

Choosing the right method depends on your print volume. Factories often recommend offset printing for bulk orders to reduce unit cost.

📦 5. Quantity and Bulk Discounts

In printing, the more you print, the lower the cost per unit. This is due to the setup time and plate-making costs involved in offset printing.

For small batches or test runs, digital printing offers an affordable starting point before committing to a full production run.

🧾 6. Finishing and Special Effects

Luxury finishes such as spot UV, matte lamination, soft-touch, or metallic foil can significantly enhance appeal but also add cost.

A reputable book printing factory will offer finishing suggestions that maximize value without overspending.

✅ Conclusion

Every custom book printing project is unique. The total cost depends on materials, quantity, and finishing choices. By communicating your goals and budget with your book printing supplier, you can find the perfect balance between quality and affordability.

The best printing results come from careful planning — and an experienced factory partner who knows how to make every page worth the investment.