📘 Introduction

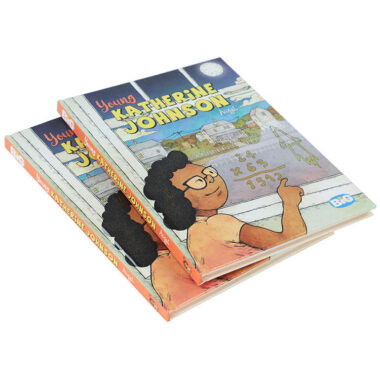

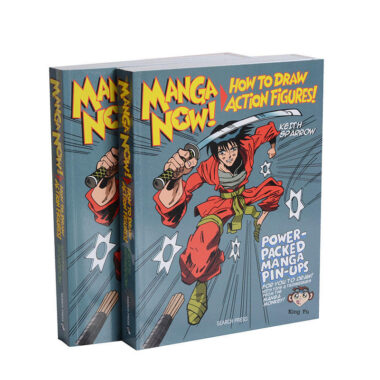

Hardcover books have always represented quality, prestige, and timeless appeal. Whether it’s an art collection, a corporate catalog, or a novel, a well-produced hardcover edition instantly elevates your brand. But behind that elegance lies a detailed and highly technical process that ensures strength, accuracy, and consistency.

This guide takes you through the hardcover book printing process from start to finish — giving you a clear view of how professional printing factories transform your design into a durable, premium product.

🏗️ 1. Prepress Preparation

Before printing begins, files are carefully checked for resolution, bleed, and color accuracy. A prepress technician ensures that your PDF layouts meet industry standards. Fonts are embedded, images converted to CMYK, and test proofs generated for review.

Working with an experienced book printing supplier can prevent costly errors and guarantee that your colors match the final output.

🎨 2. Interior Page Printing

Most hardcover books are printed using offset printing, which delivers sharper details and consistent tones for large-volume orders.

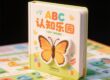

Text-heavy books use lighter, uncoated paper.

Art and photo books benefit from glossy or matte coated paper.

High-speed printing machines run sheets in batches, and every batch is calibrated for color uniformity.

⚙️ 3. Cover Printing and Lamination

The hardcover’s outer jacket is printed separately, often on heavier coated paper or special art paper. It can be finished with:

Gloss or matte lamination

Foil stamping

Spot UV or embossing

These finishes not only improve durability but also enhance the visual appeal of your custom hardcover books. Many book printing factories have in-house lamination and foil machines for precise control.

🧵 4. Binding and Case Making

The interior pages are folded, gathered, and sewn into signatures — a process known as section sewing, which ensures long-term durability.

The printed cover is then mounted on rigid grayboard, forming the hard outer case. The sewn text block is glued into this cover, creating a solid, professional hardcover book.

🔍 5. Quality Inspection

Every finished book passes through strict QC checks:

Binding alignment

Lamination consistency

Color accuracy

Page trimming precision

Only after these checks are approved do the books move to packaging and shipment. This attention to detail is what separates a reliable printing factory from standard suppliers.

📦 6. Packaging and Delivery

Hardcover books are shrink-wrapped or placed in protective cartons to avoid scuffing during transport. Most factories offer export-ready packaging with moisture-proof layers.

For bulk clients, international delivery is arranged via sea or air, depending on project timeline and order size.

✅ Conclusion

Producing hardcover books requires both craftsmanship and precision. From the first design file to final delivery, every step impacts the outcome.

Partnering with an experienced book printing factory ensures that your hardcover editions look professional, feel premium, and last for years. Whether you’re a publisher, brand, or creative studio, a trusted printing supplier can turn your vision into a lasting product.